About software

Self-Diagnosis Program

Geometric accurancy and operation of each motion axes of the gear measuring machines can be measured and verified fully automatically. Quality judgement in each item can be done, and the result can be stored into PC.You can use this result as a tool of simple periodical inspection.

Standard measurement

Tooth profile and tooth trace ranging from one tooth to four division, and the pitch are measured.The data output in a vertical writing format.

All-teeth measurement

Tooth profile and tooth trace ranging from one tooth to specified number of teeth, and the pitch are measured. This data output in a horizontal writing format.

Subdivision measurement

Up to 33 points of tooth profile and one point of tooth trace for one tooth surface are measured. This state of ruggedness is displayed in 3D matrix.

SFS measurement

The specifications of an unknown gear are measured and calculated fully automatically.

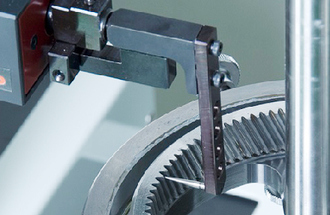

Internal gear measurement

Tooth profile and tooth trace ranging from one tooth to specified number of teeth, and the pitch are measured. This data output in a horizontal writing format.

*Tooth profile, tooth trace and pitch for left and right side of tooth surface are measured at once without exchanging a probe or changing it's direction.

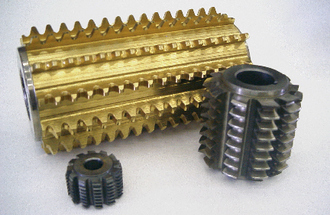

HOB cutter measurement

●3 items measuring program

The radial alignment of cutting face and lead ranging from one tooth to 4 division,and pitch is measured.

●14 items measuring program

The measurement of 14 items in accordance with each standard is done.

*This measurement requires 3D detector which detect displacement of three axes.

Worm gear measurement

Tooth profile and tooth trace ranging from one tooth to 4 division, and pitch of worm gears (I, II, III, and IV) is measured.

Shaving cutter measurement

●Shaving cutter tooth profile and tooth trace measurement

Tooth profile and tooth trace are measured. It doesn't matter what kind of shaving cutter, such as conventional one and plunge one. The position of serration can be detected automatically so it is not necessary to enter the position and else.It is possible to choose measurement item from one-tooth measurement, one-tooth three-division measurement and subdivion measurement.

●Shaving cutter pitch measurement

The pitch of differential serration can be measured by calculating unknown serration pattern.

Pinion cutter measurement

Tooth profile, tooth trace and pitch of pinion cutters are measured.